- PCB Specifications

-

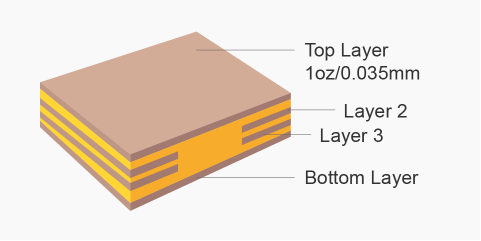

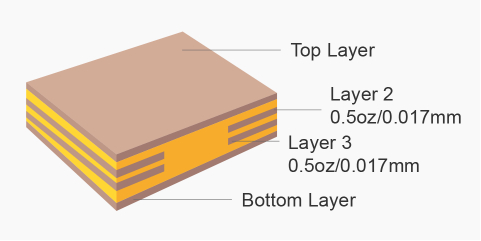

Items: Layer count

Manufacturing Capabilities: 1 - 32 layers

Notes:Quantity of copper layers on the board

Items: Impedance

Manufacturing Capabilities: For 4, 6, 8, 10, 12, 14, 16, 18, 20 layers PCB, PCB Stackup designed by NextPCB(by default), or PCB Stackup designed by customers

Notes: Layer Stackup Structure Impedance Calculation Parameter

Items: Impedance tolerance

Manufacturing Capabilities: ±10%

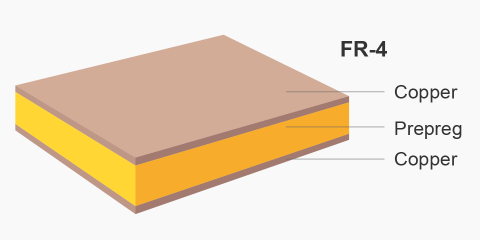

Items: Material

Manufacturing Capabilities: FR-4

Notes: FR-4: TG130/TG150/TG170

Items: PCB material dielectric constant

Manufacturing Capabilities: 4.2

Notes: Prepreg dielectric constant (prepregtype: 7628/1080/2313/2116, dielectric constant: 4.2)

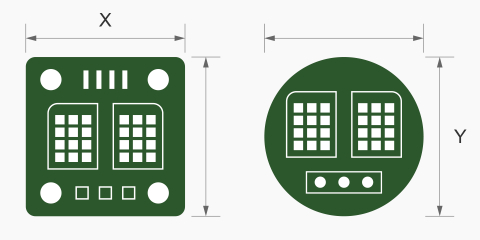

Items: Max. dimension

Manufacturing Capabilities: 1-2 layers: 500*600mm 4-20 layers: 400*500mm

Notes: The maximum dimension that NextPCB can do

Items: Min. dimension

Manufacturing Capabilities: Length and width ≥10mm

Notes: Min. dimension = 10*10mm

Items: Dimension tolerance

Manufacturing Capabilities: CNC: ±0.15mm, V-CUT: ±0.2mm

Notes: ±0.15mm for CNC routing,and ±0.2mm for V-scoring

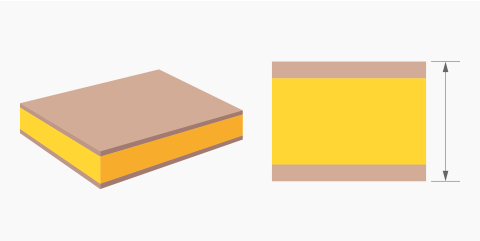

Items: PCB thickness

Manufacturing Capabilities: 0.6/0.8/1.0/1.2/1.6/2.0/2.5/3.0/3.2mm

Notes: The thickness of finished board

Items: Thickness tolerance( Thickness≥1.0mm)

Manufacturing Capabilities: ±10%

Notes: e.g. If the board thickness is 1.6mm, the finished board thickness ranges from 1.44mm(1.6-1.6×10%) to 1.76mm(1.6+1.6×10%)

Items: Thickness tolerance( Thickness < 1.0mm)

Manufacturing Capabilities: ±0.1mm

Notes: e.g. If the board thickness is 0.8mm, the finished board thickness ranges from 0.7mm(0.8-0.1) to 0.9mm(0.8+0.1)

Items: Finished copper weight

Manufacturing Capabilities: 1 oz/2 oz

Notes: Finished copper weight of outer layer could be 1 oz/2 oz

Items: Inner copper weight

Manufacturing Capabilities: 0.5 oz/1 oz/2 oz

Notes: Finished copper weight of inner layer could be 0.5 oz/1 oz/2 oz

Items: Surface finish

Manufacturing Capabilities: HASL/Lead free HASL/ENIG/OSP

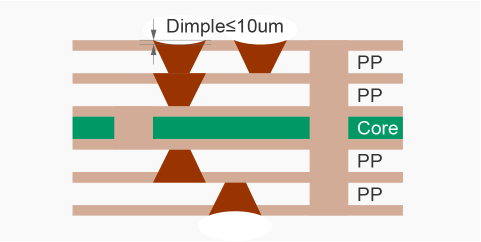

Items: HDI structure

Manufacturing Capabilities: Type 1 /Type 2 /Type 3

Notes: Mechanical blind buried vias or laser blind buried vias(electroplating Via-filling is available) or laser blind vias filling dimple ≤ 15µm

Items: Electrical test

Manufacturing Capabilities: Flying Probe/Special test fixture

Notes: No limits for Flying Probe. Max. 14000 Pads can be tested by PCB test fixture

Items: Beveling angle of gold finger

Manufacturing Capabilities: 20°/30°/45°/60°

Items: Beveling angle tolerance of gold finger

Manufacturing Capabilities: ±5°

Items: Beveling depth tolerance of gold finger

Manufacturing Capabilities: ±0.1mm

Items: Outline tolerance

Manufacturing Capabilities: ±0.15mm

Items: V-CUT angle

Manufacturing Capabilities: 30°/45°/60°

Items: Number of V-CUT

Manufacturing Capabilities: ≤30 cuts

Items: V-CUT outline size

Manufacturing Capabilities: 55mm ≤ length/width ≤ 480mm

Items: V-CUT residue thickness

Manufacturing Capabilities: 0.25mm ≤ v-cut residue thickness ≤ 0.4mm

- Drill/Hole Size

-

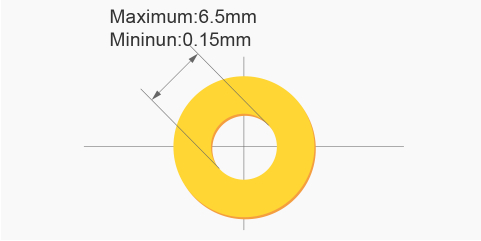

Items: Drill hole size(Mechanical)

Manufacturing Capabilities: 0.15-6.5mm

Notes: Min. drill hole size: 0.15mm(available for PCB thickness ≤ 1.2mm) Max. diameter of drilling bits is 6.5mm(contact support@nextpcb.com if your customed hole size > 6.5mm)

Items: Drill hole size tolerance

Manufacturing Capabilities: ≤0.05mm

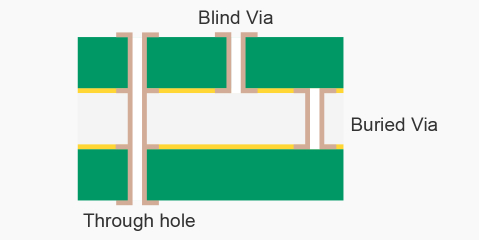

Items: Blind/Buried vias

Manufacturing Capabilities: Mechanical blind buried vias: copper thickness of blind vias ≥ 20µm

Items: Blind/Buried vias

Manufacturing Capabilities: Laser blind buried vias: dimple ≤ 10µm

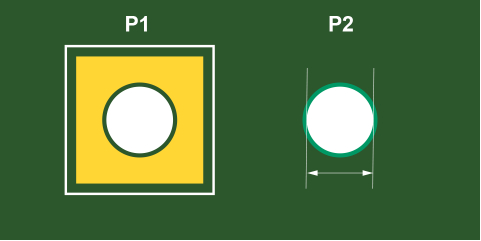

Items: Via pad size

Manufacturing Capabilities: ≥0.1

Notes: The pad hole size will be enlarged 0.125mm in production

Items: PTH hole size

Manufacturing Capabilities: 0.2mm (for single side)

Notes: The annular ring size will be enlarged to 0.2mm in production

Items: Min. non-plated holes

Manufacturing Capabilities: 0.4mm

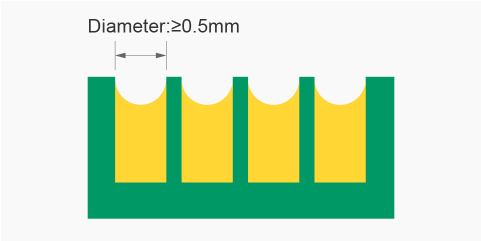

Items: Min. plated slots

Manufacturing Capabilities: 0.5mm

Items: Min. non-plated slots

Manufacturing Capabilities: 0.5mm

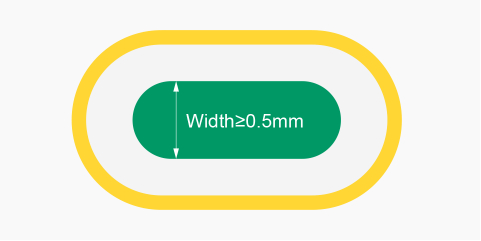

Items: Min. castellated holes

Manufacturing Capabilities: 0.5mm

Notes: The minimum diameter of castellated holes is 0.50mm

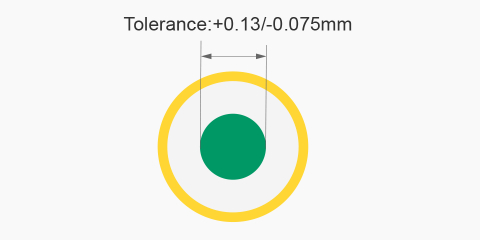

Items: Hole size tolerance(Plated)

Manufacturing Capabilities: ±0.075mm

Notes: e.g. If customed Plated hole size is 1.000mm, the finished hole size could be between 0.925mm to 1.075mm

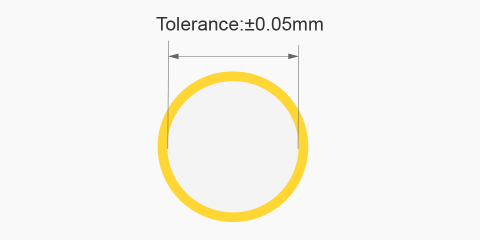

Items: Hole size Tolerance(Non-Plated)

Manufacturing Capabilities: ±0.05mm

Notes: e.g. If customed Non-Plated hole size is 1.000mm, the finished hole size could be between 0.95mm to 1.05mm

Items: Rectangle hole/Slot

Manufacturing Capabilities: With or without fillet angle

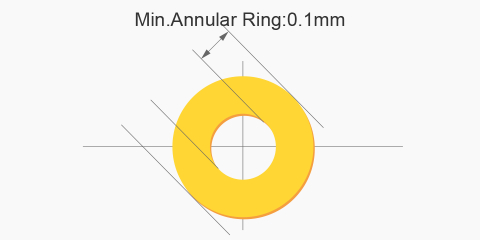

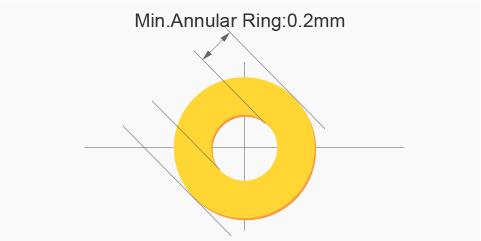

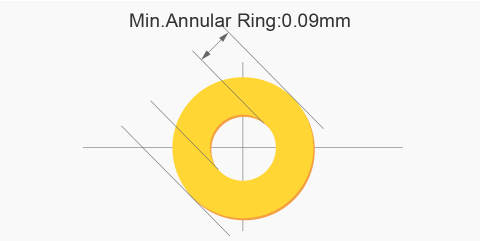

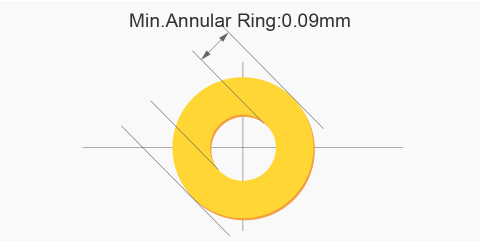

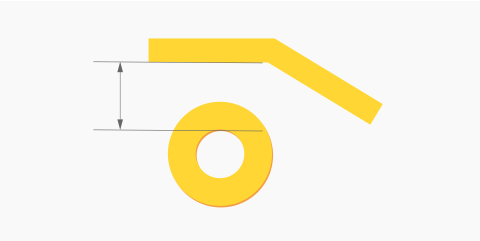

- Minimum Annular Ring

-

Items: 1 oz Copper

Manufacturing Capabilities: 3.5mil (single side) (3.5mil≈0.09mm)

Items: 2 oz Copper

Manufacturing Capabilities: 4.5mil (single side) (4.5mil≈0.11mm)

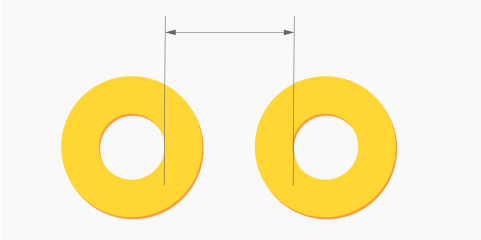

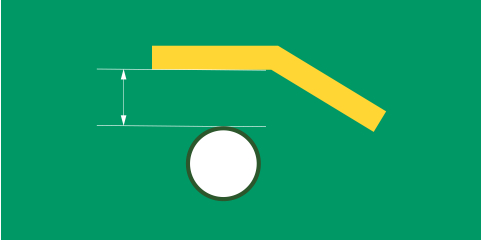

- Minimum clearance

-

Items: Hole to hole clearance(Different nets)

Manufacturing Capabilities: ≥12mil(Avoid conductive anodic filament)(12mil≈0.30mm)

Items: Via to via clearance(Same nets)

Manufacturing Capabilities: ≥8mil (8mil≈0.20mm)

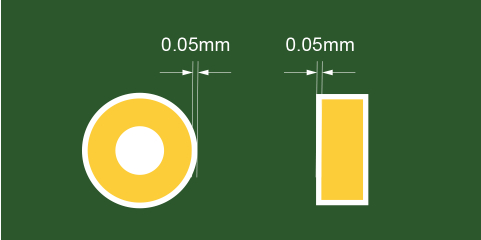

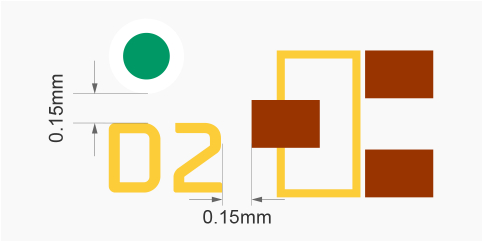

Items: SMD pad to SMD pad clearance(Pad without hole, different nets)

Manufacturing Capabilities: ≥0.15mm

Items: Pad to pad clearance(Pad with hole, different nets)

Manufacturing Capabilities: ≥0.40mm

Items: Via to track

Manufacturing Capabilities: ≥7mil (7mil≈0.18mm)

Items: PTH to track

Manufacturing Capabilities: ≥9mil (9mil≈0.23mm)

Items: NPTH to track

Manufacturing Capabilities: ≥8mil (8mil≈0.20mm)

Items: SMD pad to track

Manufacturing Capabilities: ≥4mil (4mil≈0.10mm)

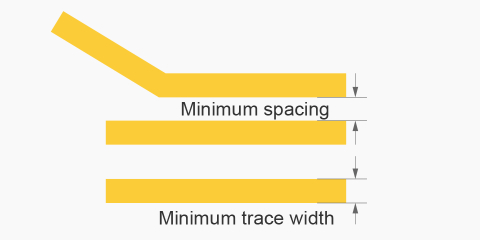

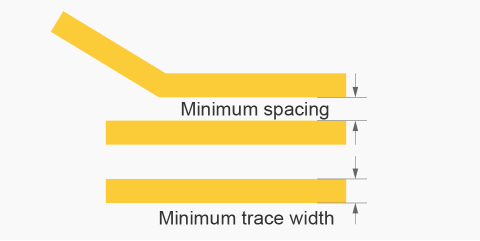

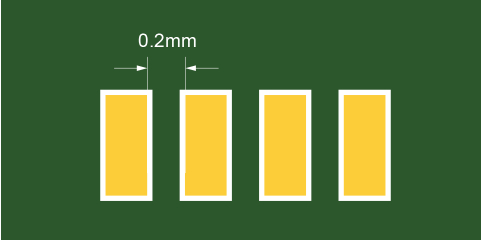

- Minimum trace width and spacing

-

Copper weight: H/HOZ(0.5oz Inner layer)

Min. trace width: 2.5mil (2.5mil≈0.06mm)

Min. spacing: 3mil (3mil≈0.08mm)

Copper weight: 1 oz(Outer layer)

Min. trace width: 3mil (3mil≈0.08mm)

Min. spacing: 3mil (3mil≈0.08mm)

Copper weight: 2 oz(Outer layer)

Min. trace width: 5.5mil (5.5mil≈0.14mm)

Min. spacing: 5.5mil (5.5mil≈0.14mm)

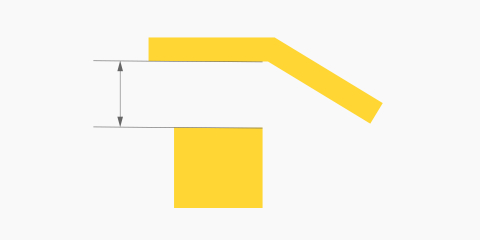

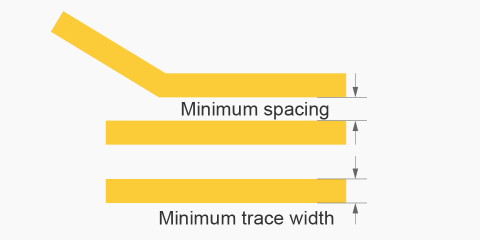

- BGA

-

Layer count: 1 oz

Min. BGA pad dimensions: ≥0.2mm

Min. distance between BGA: 0.15mm

Min. spacing between the center of two BGAs: 0.45mm

- Solder Mask

-

Items: Solder mask opening/expansion

Manufacturing Capabilities: ≥1.5mil (1.5mil≈0.04mm)

Notes: There should be a minimum size of 1.5mil "solder mask opening" around the pad to allow for any misregistration

Items: Solder bridge

Manufacturing Capabilities: Green: 3.5mil Black/White: 5mil other solder mask: 4mil

Notes: To build solder bridge, the spacing between copper pads edge must be 3.5mils or more

Items: Solder mask color

Manufacturing Capabilities: Green/Red/Yellow/Blue/White/ Matte Black/Black

Items: Solder mask dielectric constant

Manufacturing Capabilities: 3.5

Items: Solder mask thickness

Manufacturing Capabilities: Solder mask thickness on base material: 0.8mil, solder mask thickness on copper: 0.6mil

- Legend

-

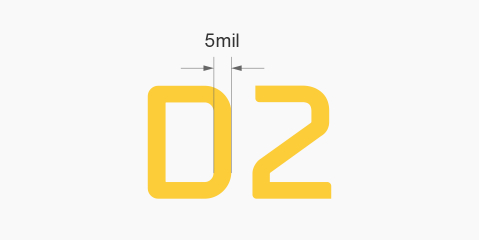

Items: Minimum line width

Manufacturing Capabilities: Silkscreen printing≥5mil (5mil≈0.12mm) Printer printing≥3mil (3mil≈0.08mm)

Notes: Characters width < 3mil(0.076mm) will be unidentifiable

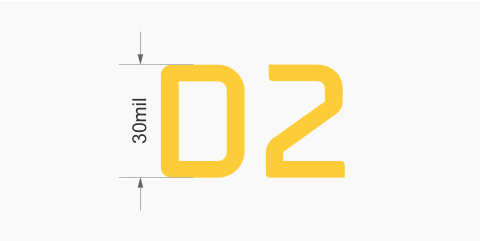

Items: Minimum text height

Manufacturing Capabilities: Silkscreen printing≥30mil (30mil≈0.76mm) Printer printing≥24mil (24mil≈0.61mm)

Notes: Characters height < 24mil(0.61mm) will be unidentifiable

Items: Character width to height ratio

Manufacturing Capabilities: ≥ 6:1

Notes: The preferred ratio of width to height is 6:1

Items: Pad to silkscreen

Manufacturing Capabilities: >6mil (6mil≈0.15mm)

Notes: The minimum distance between pad and silkscreen is 0.15mm

- Board Outlines

-

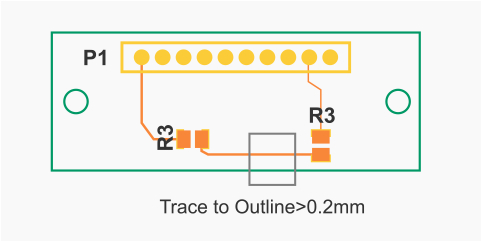

Items: Trace to outline

Manufacturing Capabilities: ≥0.2mm

Notes: Individual board(Rounting): Trace to Outline ≥ 0.2mm

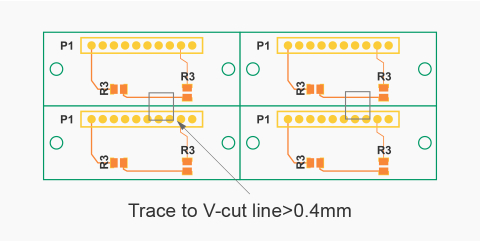

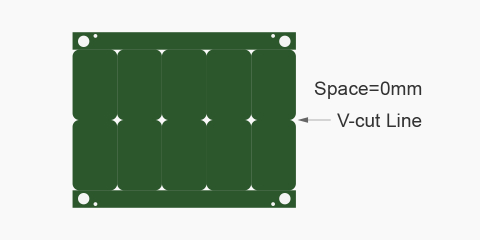

Items: Trace to V-cut line

Manufacturing Capabilities: ≥0.4mm

Notes: Panel board with V-scoring: Trace to V-cut line ≥0.4mm

- Panelization

-

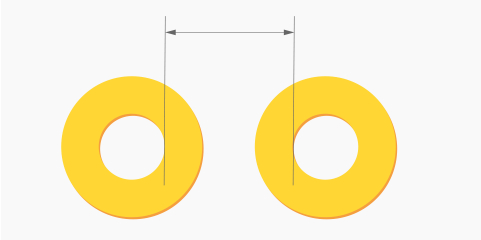

Items: Panelization without space

Manufacturing Capabilities: 0mm

Notes: No space between panelized PCBs

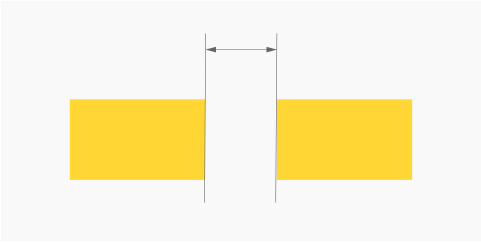

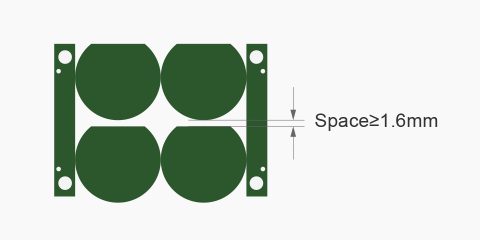

Items: Panelization with space

Manufacturing Capabilities: ≥1.6mm

Notes: The space between panelized PCBs should ≥ 1.6mm, if not, the routing process may be difficult and low efficiency

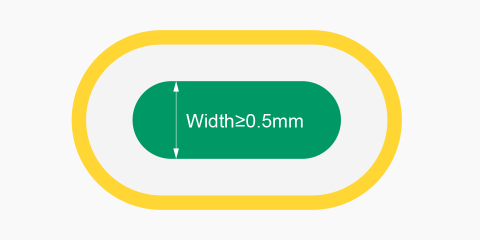

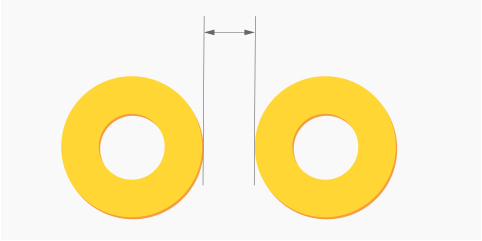

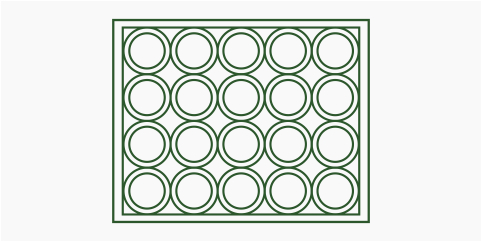

Items: Panelized round board

Manufacturing Capabilities: ≥80mmx80mm

Notes: Stamp Hole: hole size=0.5mm, copper gap=0.35mm, 5-7holes for a set by default

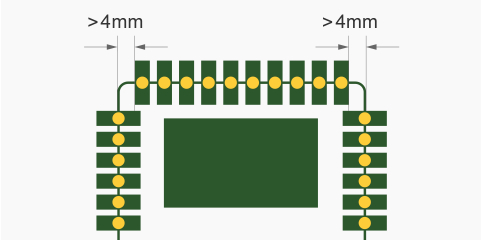

Items: Panelized castellated holes board

Manufacturing Capabilities: Panelize with stamp holes and add tooling strips on four board edges

Notes: The distance between castellated hole and board corner should be > 4mm

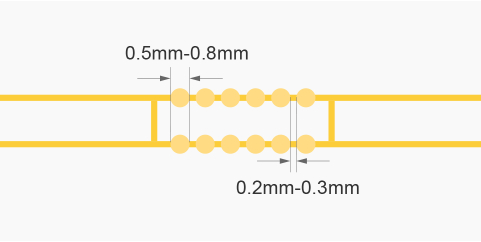

Recommended diameter of stamp hole is 0.5mm-0.8mm

Recommended distance between the two stamp holes is 0.2mm-0.3mm

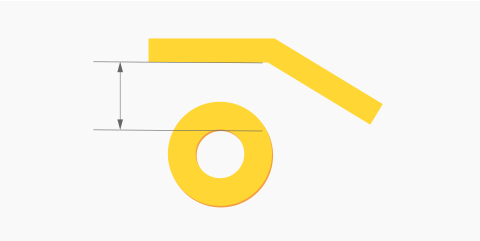

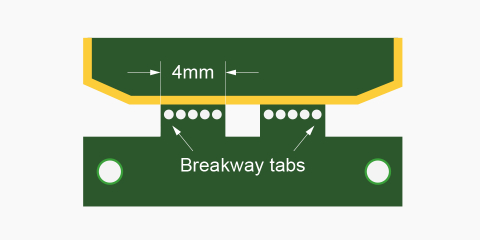

Items: Min. width of breakaway tab

Manufacturing Capabilities: ≥4mm

Notes: The minimum width of breakaway tab is 4mm. For breakaway with mouse-bites, the minimum width is 5mm

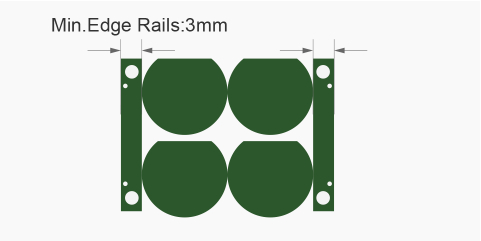

Items: Min. edge rails

Manufacturing Capabilities: ≥3mm

Notes: If you choose panel by NextPCB, we will add 3mm edge rails on both sides by default

- Manufacturable Notes for Different PCB Design Softwares

-

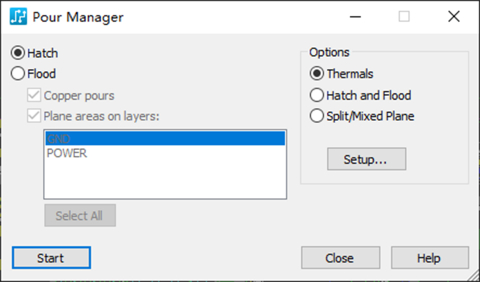

Items: PADS

Manufacturing Capabilities: copper-pour pattern

Notes: NextPCB Fab uses hatch pattern by default, please note your copper-pour pattern when placing an order

Items: PADS

Manufacturing Capabilities: 2D line

Notes: Valid lines cannot be placed in the corresponding layer as 2D lines, NextPCB does not process 2D lines

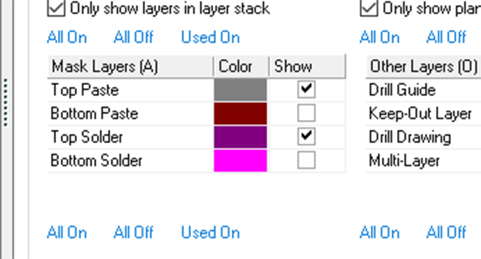

Items: Altium Designer Protel

Manufacturing Capabilities: Version

Notes: There are elements missing issues in generating Gerber files from different versions of Altium Designer. Please note your version No. of Altium Designer when placing an order

Items: Altium Designer Protel

Manufacturing Capabilities: Parts outside PCB

Notes: If the components were placed far away from the PCB board, file generating would failed because the boundary of the board is too large

Items: Altium Designer Protel

Manufacturing Capabilities: solder mask opening

Notes: Please do not put the opening of the solder layer on the paste layer by mistake, NextPCB does nothing to the paste layer

Items: Altium Designer Protel

Manufacturing Capabilities: copper-pour pattern

Notes: Fill pattern: too much filling region will causing region missing when generating a file, Tip: choosing Polygon copper-pour pattern