High-Speed PCBs

As digital systems push beyond multi-gigabit data rates, high-speed PCBs have become critical for modern electronics from 5G networks to AI accelerators. Building high-speed boards requires precise impedance control, advanced materials, and expert fabrication to minimize signal degradation.

Table of Contents

What are High-Speed PCBs?

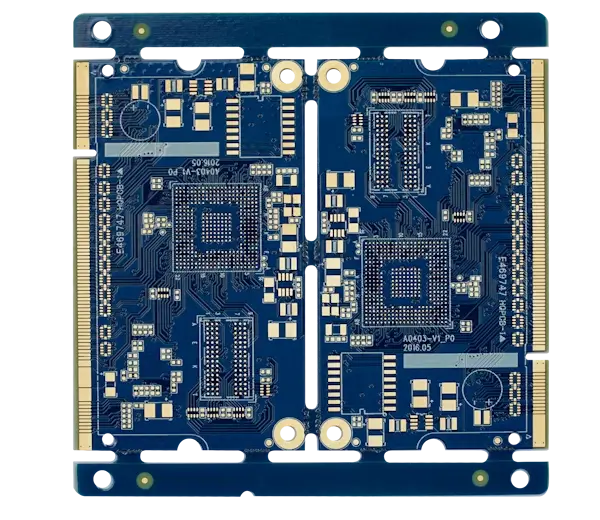

High-speed DDR SDRAM PCB panel

High-speed printed circuit boards are circuit boards that are engineered to process high-speed signals in such a way that maintains signal integrity (SI) and power integrity (PI). High-speed PCBs must take into account the electromagnetic wave behaviour of electrons and consider transmission line effects, electromagnetic interference (EMI) and signal degradation caused by high-frequency operation.

High-speed design techniques are required when:

The frequency of digital signals exceeds 50-100MHz or when signal rise/fall times are shorter than 1 nanosecond. This includes modern digital interfaces, including USB3.2, HDMI 2.1, PCIe 4.0, DDR5, etc.

The frequency of analog/radio frequency (RF) signals exceeds 300-500 MHz such as Wifi 6, 5G, radar and satellite communications.

| Interface | Version | Max Speed | Applications |

|---|---|---|---|

| USB | USB 3.0 (USB 3.2 Gen 1) | 5 Gbps | External HDDs, flash drives |

| USB 3.2 Gen 2 | 10 Gbps | Fast SSDs, docking stations | |

| USB4 / Thunderbolt 4 | 40 Gbps | High-speed docking, eGPUs | |

| HDMI | HDMI 1.4 | 10.2 Gbps | 1080p @ 120Hz, 4K @ 30Hz |

| HDMI 2.0 | 18 Gbps | 4K @ 60Hz, HDR | |

| HDMI 2.1 | 48 Gbps | 4K @ 120Hz, 8K @ 60Hz | |

| Ethernet | 1 Gigabit (1GbE) | 1 Gbps | Home/small office internet |

| 10 Gigabit (10GbE) | 10 Gbps | Servers, high-speed NAS | |

| 100 Gigabit (100GbE) | 100 Gbps | Data centers, cloud computing | |

| PCIe | PCIe 3.0 | ~8 Gbps per lane | Older GPUs, SSDs |

| PCIe 4.0 | ~16 Gbps per lane | Modern GPUs (RTX 3000), NVMe SSDs | |

| PCIe 5.0 | ~32 Gbps per lane | RTX 4000, next-gen SSDs | |

| RAM (DDR) | DDR4 | ~25 GB/s (total) | Older desktops, laptops |

| DDR5 | ~50 GB/s (total) | New PCs (Ryzen 7000, Intel 12th/13th Gen) |

Despite significant overlap, the techniques and priorities in high-speed digital and analog design differ. To amplify the distinction, analog high-speed boards are often referred to as high-frequency (HF) boards, and digital circuits are referred to as high-speed digital circuits (HSD), highlighting the respective frequency and data-rate dependence. In this discussion, we will focus on high-speed digital circuits unless otherwise specified. For RF circuits, please refer to our high-frequency analog PCBs and materials page.

Challenges of High-Speed PCB Design

High-speed design takes PCB design and engineering to a whole new level. No longer are circuits simply the physical manifestation of a netlist. Trace widths influence more than just current-carrying capacity and electromagnetic wave behaviour dominates every decision. High-speed design is a completely different discipline that flips first-order logic on its head, and while guidelines and best practices for high-speed design are proliferant, so are the myths. Successful high-speed design requires tight collaboration and understanding across design, fabrication and testing teams for optimal results.

PCB Fabricator Services to Optimize Signal Integrity

In addition to diligently following high-speed design practices, there are various ways in which working with your PCB manufacturer can help you achieve signal integrity goals.

Impedance Tuning

One of the most important ways a fabricator can help high-speed designers is by offering impedance control services, including verification, testing and even helping with tuning. For loose requirements, online impedance calculators and datasheets may suffice. However, the impedance of signal traces can be affected by several factors, many of which are beyond the designer's control. PCB manufacturers have better control and understanding of their manufacturing processes and tolerances, and can verify the actual impedance with impedance coupons. A combined approach with cooperation from both the designer and fabricator is the best strategy to maximize success in high-speed designs.

Controlled impedance services and resources to look out for:

Impedance Control Services

A service where you tell your fab house which signals require impedance control and let the fab's engineers modify the trace widths/spacing, taking into account manufacturing tolerances (variations in etching, layer alignment, material consistency, etc.). Impedance test coupons are added to the panel, which replicate the geometry of the target traces and an instrument such as a Time Domain Reflectometer (TDR) is used to confirm the impedance matches target values. There is often an additional charge for this service, but it is an effective way to guarantee impedance compliance for relatively loose tolerances.

Use Standard Stack-ups

No impedance control service? Many quickturn services lack the expertise to provide the impedance control services mentioned above. However, with the necessary data and guarantees, it is perfectly acceptable to fine-tune impedance yourself with results within ±10%, the acceptable range for most consumer electronics.

To save production costs, seek the manufacturer's standard stack-ups and material datasheets for thicknesses, dielectric constants and loss values for impedance calculations. Ensure you are able to guarantee the same stack-up for production. Manufacturers may have multiple default stack-ups and even if a stack-up is considered standard, orders may be pooled with other boards with custom stack-ups to save costs.

Look out for impedance calculator/stack-up selector tools provided by manufacturers that incorporate their available stack-ups and materials.

Build Custom Stack-ups

For more complex structures, support for custom stack-ups with built-in impedance allows you to specify the core/prepreg material and thicknesses to your specifications.

For quickturn services, this option is relatively expensive as it limits pooling options, but it gives maximum control over the PCB's electrical and mechanical properties.

Advanced Manufacturing Support for High-Speed Designs

In ultra-high-speed digital designs, nanosecond/sub-picosecond rise times transition signal behavior into the RF domain, where dispersion, skin effect, and impedance discontinuities dominate signal integrity. High-frequency strategies can be used to mitigate distortion and reduce losses, such as by using substrate materials with exceptionally low loss and stable dielectric constants, smooth copper, backdrilling vias and filling vias. Tighter impedance control, precise trace geometries, material selection and quality control are essential for tight impedance goals within ±5%, common in aerospace, medical, defense and mmWave radar applications.

NextPCB delivers high-performance PCB fabrication with solutions for high-speed and high-frequency designs for various signal integrity requirements. Have our engineers tune your impedance traces to your requirements, use our stack-up selector and impedance calculator tool, or explore our vast range of high-speed laminates and capabilities.

NextPCB High-Speed PCB Manufacturing Capabilities

| Capability | Details |

|---|---|

| Stack-ups | Custom multilayer PCB stack-ups |

| Materials |

High-Speed PCB materials High-Frequency materials |

| Impedance Control Services |

|

| Fabrication techniques |

|

| Industries/Technologies |

|

Get a quote or inquire for more capabilities.

How to choose High-Speed PCB Materials

Beyond PCB design, one of the most important decisions that influences signal integrity is the PCB's substrate material. At higher speeds (~5 GHz), increasing dielectric losses (loss tangent, or Df) dominate, making high-speed/high-frequency materials necessary for the effective preservation of signal integrity. Selecting the right materials and stackup depends on clock speed, frequency range, Df, Dk, thermal and mechanical requirements and budget. For exceptionally low dielectric losses and stable Dk, Rogers and PTFE (Teflon) PCB materials may be preferred for high-speed digital designs as high-frequency effects become significant.

NextPCB offers a wide range of high-speed PCB laminates from trusted brands, suitable for applications spanning consumer electronics to aerospace applications. Get a quote by selecting a material and submitting your request.

NextPCB High-Speed PCB Materials

| Material Code | Brand | Type | Dk | Df | Tg (°C) | Halogen-Free | Datasheet |

|---|---|---|---|---|---|---|---|

| IT-988G SE | ITEQ | 40-56 Gbps | 3.2 | 0.0025 | 190 (DSC) | Yes | IT988GSE.pdf |

| R-5785N/M7N | Panasonic | 40-56 Gbps | 3.3 | 0.002 | 200 (DSC) | No | R5785N(M7N).pdf |

| TU-933 | TUC | 25-40 Gbps | 3.4 | 0.0025 | 170 (TMA) | No | TU933.pdf |

| Tachyon 100G | Isola | 25-40 Gbps | 3.02 | 0.0021 | 215 (DSC) | No | Tachyon100G.pdf |

| IT-968 SE | ITEQ | 25-40 Gbps | 3.3 | 0.0038 | 185 (DSC) | No | IT968SE.pdf |

| R-5785/M7 | Panasonic | 25-40 Gbps | 3.6 | 0.003 | 200 (DSC) | No | R5785(M7).pdf |

| R-5775N/M6N | Panasonic | 25-40 Gbps | 3.4 | 0.004 | 185 (DSC) | No | R5775N(M6N).pdf |

| IT-968 | ITEQ | 10-25 Gbps | 3.7 | 0.0047 | 185 (DSC) | No | IT968.pdf |

| R-5775G/M6G | Panasonic | 10-25 Gbps | 3.6 | 0.004 | 185 (DSC) | No | R5775G(M6G).pdf |

| TU-883 | TUC | 10-25 Gbps | 3.39 | 0.0045 | 170 (TMA) | Yes | TU883.pdf |

| EM-891 | EMC | 10-25 Gbps | 3.6/3.2 | 0.0054/0.0045 | 170 (TMA) | No | EM891.pdf |

| EM-888K | EMC | 10-25 Gbps | 3.2/3.1 | 0.0062/0.0074 | 170 (TMA) | No | EM888K.pdf |

| I-Tera MT40 | Isola | 10-25 Gbps | 3.45 | 0.0031 | 215 (DSC) | No | ITeraMT40.pdf |

| R-5725S/M4S | Panasonic | 5-10 Gbps | 3.8 | 0.007 | 200 (DSC) | No | R5725S(M4S).pdf |

| TU-872 SLK | TUC | 5-10 Gbps | 3.8 | 0.009 | 190 (TMA) | No | TU872SLK.pdf |

| TU-863 | TUC | 5-10 Gbps | 3.9 | 0.0095 | 170 (TMA) | No | TU863.pdf |

| EM-888 | EMC | 5-10 Gbps | 3.7/3.2 | 0.0073/0.0079 | 170 (TMA) | No | EM888.pdf |

| I-Speed | Isola | 5-10 Gbps | 3.64 | 0.0059 | 180 (DSC) | No | ISpeed.pdf |

| IT-958GTC | ITEQ | 5-10 Gbps | 3.7 | 0.007 | 170 | No | IT958GTC.pdf |

| IT-170GRA1 | ITEQ | 1-5 Gbps | 4 | 0.008 | 180 (DSC) | Yes | IT170GRA1.pdf |

| TU-862 HF | TUC | 1-5 Gbps | 4.4 | 0.01 | 170 (TMA) | Yes | TU862HF.pdf |

| Isola-FR408HR | Isola | 1-5 Gbps | 3.68 | 0.0092 | 190 (DSC) | No | IsolaFR408HR.pdf |

| Isola-FR406 | Isola | 1-5 Gbps | 3.93 | 0.0167 | 170 (DSC) | No | IsolaFR406.pdf |

| EM370(Z) | EMC | 1-5 Gbps | 4.2/3.8 | 0.015/0.019 | 180 (TMA) | Yes | EM370(Z).pdf |

| EM828G | EMC | 1-5 Gbps | 3.8/3.3 | 0.011/0.013 | 170 (DSC) | Yes | EM-828G.pdf |

| NP175FM | Nanya | 1-5 Gbps | 3.89 | 0.014 | 170 (DSC) | No | NP175FM.pdf |

Get a quote or inquire for more materials.