V-Scoring

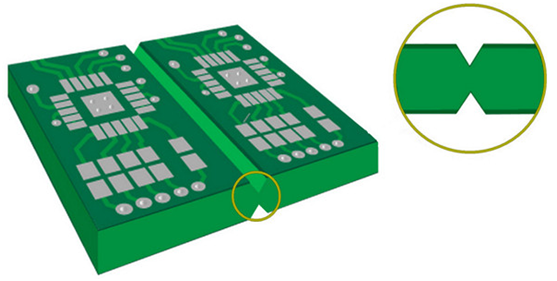

When ordering a PCB fabrication project, customers have several options for the format of the panels, such as V-scoring, tab routing, or solid tab. V-scoring and tab routing is the preferred panel method for most applications. Among them, v-scoring, also named as V-cut, or V-groove, is the process of cutting a "V" shaped groove on the top and the bottom of a panel designed PCB to make it easier to remove the individual board from the board array.

The function of V-scoring in PCB production

V-scoring is used to make the assembly process more efficient when grouping a set of circuit boards in an array. V-scoring is a very cost-effective and efficient way to easily separate parts from completed assemblies. The v-scoring tool consists of a top and a bottom cutting blade that run across the panel in a straight line to create the scoring and leave a minimum connection material in place to keep the boards stay together.

PCB jump scoring is to lift the blade off the laminate surface before reaching the end of the panel if some heavy components need to keep the strength of the array so that the components do not fall off until the assembly is complete. This situation of the blade needs to "jump" the PCB over some specific parts of the array is called PCB jump scoring.

V-scoring needs to be a straight line on the panel, which means that only rectangular or square PCBs are suitable for v-scaring. V-scoring is always used for PCB mass production, and it is also ideal for relatively low-volume prototype PCB assembly projects. The panel does not need v-scoring only when customers want to receive their boards as the panel rather than separated boards for testing or other purposes.

The rules of using V-scoring for PCB panel

Whether the board is square or rectangular, the boards can be cut on the v-score machine if all sides have straight lines. V-scoring is more accessible for its efficiency, reduction in surface stress, and relatively cost-effective. But the panel design is somewhat restrictive in some aspects.

- V-scoring is not suitable for models where the components are placed too close or hung from the edges.

- To ensure that components are not affected during the cutting process, a clearance of 0.05inches must be maintained between the components and any v-scorings. And the tall parts may need to be placed further away to make sure the tool does not interfere with them.

- The surface-mounted multilayer ceramic chip capacitors must be kept at least 1/8 inch away from the scoreline. And the parts with larger connection areas should also be placed further from the v-groove.

NextPCB can provide high-quality of V-scoring for PCB mass production with the state-of-the-art V-scoring equipment. And contact us if there are other technologies you need in PCB manufacturing or PCB assembly prototype for some particular applications. NextPCB has advanced workshops and professional technical team to make sure customers can enjoy high-quality with cost-effective experience in PCB order. No matter what your main concerns are during the fabrication of the PCBs, NextPCB can offer satisfactory answers to you!